DUCTLIS PIPE

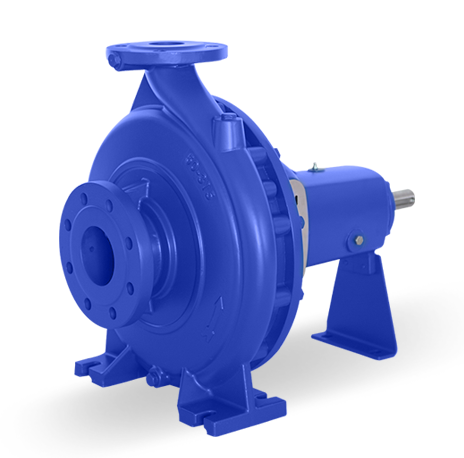

Single Stage End Suction Pumps

CATEGORY :SINGLE STAGE END SUCTION PUMPS

Single Stage End Suction Pumps

Discharge Flange : DN 32 – DN 250

Capacity : up to 1700 m³/h

Head : up to 100 m

Working Temperature : From -25 ˚C to +140 ˚C*

Casing Pressure (Pmax) : 10 bar (16 bar)*

PUMP DESIGN FEATURES

- Single stage end suction pumps have designed for pumping non-abrasive and small particulars liquids.

- Single stage end suction pump has just one impeller, pump and motor is connecting by coupling. It gives your advantages for easy disassembling.

- Pump Dimensions are according to EN 733 - DIN 24255 standard.

- Suction and discharge flanges according to EN 1092-2 / PN 16.

- Single stage end suction pumps have a closed impeller, impeller blades located between the balancing holes to minimize the axial load is taken in dynamic load balancing.

- Sealing is provided by gland packing. Sealing is provided by also mechanical seal as customer request.

- Easy disassembly to pump and change impeller, bearings, and seals.

- All impellers are statically and dynamically balanced according to ISO 1940 class 6.3.

- In addition to 29 models, 10 complementary models are designed in according to EN 733 standards. The main dimensions of complementary models may different from other manufacturers.

- Direction of rotation is clockwise viewed from the driver end.

- Optionally, pumps can be manufactured with shaft bushings and/or wear rings.

SINGLE STAGE END SUCTION PUMP USAGE AREAS

- Power Plants

- Agricultural Irrigation and Drainage

- Oil Industry

- Building System

- Water Treatment and Pressurization

- Mining

- Chemial Industry

- Heating, Ventilating and Air Conditioning

- Marine

- Fire Fighting

- Food and Beverage Industry

- Iron and Steel Indusrty

For more details and price requests, please send an email to [email protected]