Cranes Electric Hoists

Sliding vane rotary compressors (AIR/GAS)

Operating principle

A cylindrical rotor turns eccentrically in a cylindrical stator of a larger diameter: the free space left between stator and rotor is half-moon shaped. Some slots are milled in the rotor and stratified plastic blades slide freely into the slots. The blades, as the rotor turns, are forced out against the cylindrical wall of the stator by centrifugal force, so creating individual cells whose volume reduces from a maximum to a minimum during the rotation. The suction takes place through ports in the stator in the area of increasing volumes; the discharge through ports in the area of decreasing volumes.

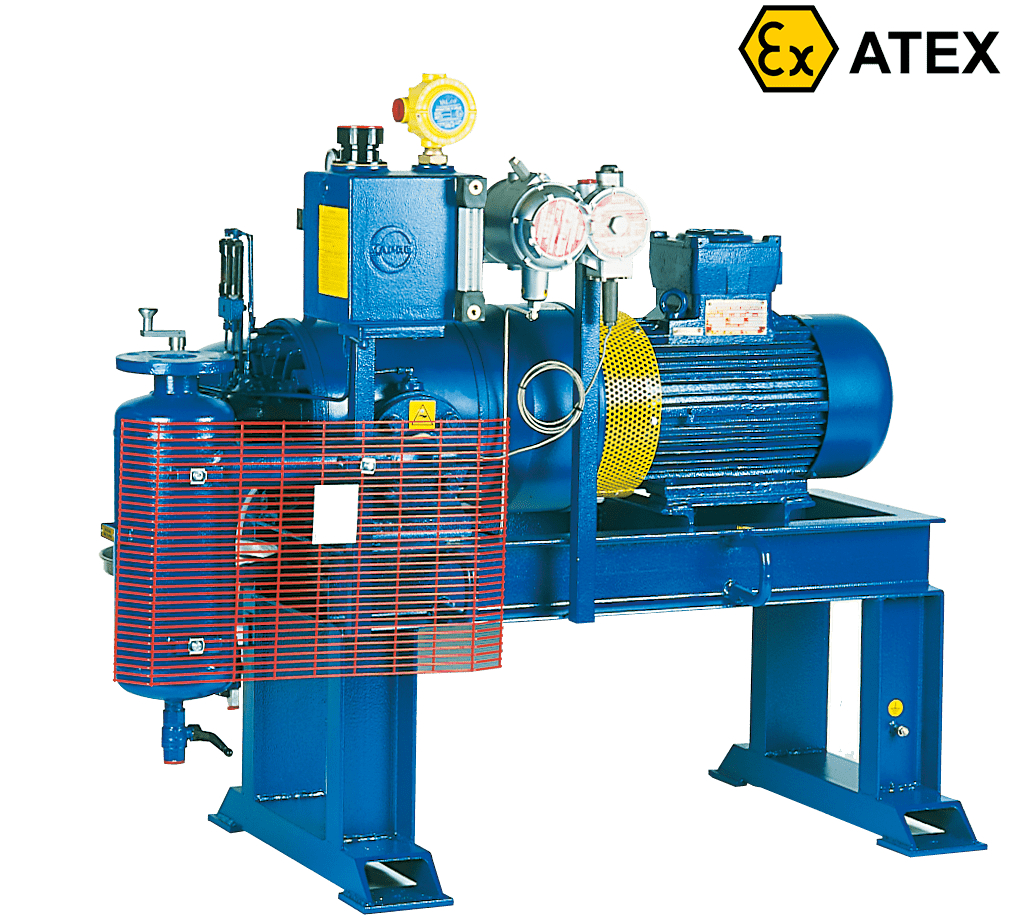

Construction features in conformity with the 2014/34/EU Directive (ATEX)

sliding vane rotary compressors destined to air compression are machines with the following features:

- casing (stator and heads) in cast iron, rotor in carbon steel, blades in light stratified spark-free material.

- sealing between stator, heads and covers by gaskets and/or O-rings.

- simple or double mechanical seal, depending on the operating discharge pressure; for the double mechanical seal, the compressor-own oil lubricating system is used as a barrier fluid.

Bearings, slats, mechanical seal, are components that require lubrication during compressor operation. The oil used for this purpose forms a thin film, continuously renewed, on the inner parts of the machine body, which tends to incorporate any tiny impurities present in the air sucked in, thus also carrying out an internal cleaning action of the compression chamber.

The compressor body in itself could be air-cooled with ambient air that is blown by an axial fan, fitted on the flexible coupling between machine and motor, around the finned cylinder and heads to provide cooling. The air is forced between the outer finned surface of the stator and an air conveying guard surrounding the compressor itself. In water-cooled compressors, an integral water jacket surrounds the cylinder and heads. Heat transfers through the metal to the water more effectively than through metal to air. Thus, water-cooled compressors reduce the internal temperature of the compressed gas more efficiently than air-cooled units. They can therefore compress the gas to a higher pressure than air-cooled units. Moreover the water-cooled compressors are capable of handling flow rates that cover a well larger range than the air- cooled compressors.

Unchangeable and high efficiency

Rotary vane compressors are positive-displacement machines. That is, the compression takes place for progressive reduction, inside the machine body, during rotation, of the gas “volume” mechanically displaced from the suction to the discharge port. The discharge port is opened, on the internal cylindrical surface of the stator, at a height depending on the foreseen discharge pressure, so that only the power needed for the actual “compression” of the gas is used. It follows that the adiabatic compression efficiency is always high, and, in general, between the 70% and the 80% if referred to the compressor displacement.

Simple and economic maintenance

The small number of parts in motion simplifies the compressor disassembly and reassembly, so making these operations well less expensive than compared to other types of positive displacement machines. A specially provided control rod allows a quick evaluation, at fixed time intervals, of the blades wear, without disassembling, even partially, the machine body. It is therefore possible to plan the blades replacement largely in advance, according to the working planning of the plant or to the maintenance needs of other equipment, so simplifying the plant operation and improving its efficiency and economy.

Gas flow without pulsation

The gas flow is continuous (no pulsation) both at the suction and at the discharge, and so there is no need to install storage tanks or gas dampers. rotary vane compressors are compact machines on which the light unbalance, due to the different radial position of the blades with respect to the axis of rotation, does not cause any significant vibration throughout the running operation. Therefore no special foundations are required. The rotary vane compressors are, in principle, less noisy than other types of compressors. Anyway, when required, they can be supplied complete with acoustic enclosures.

The most common fields of application

- Biogas recirculation into anaerobic digesters for sludge mixing.

- Extraction of biogas from gasometer or landfill and delivery to storage systems or gas engine supply.

- Extraction of natural gas from pipeline or gasometer, and delivery to storage systems or gas engine supply.

Typical supply components

To prevent dust or other impurities from entering the machine, and in any case as a protection against accidental suction of any solid body, it must always be mounted, at the suction of the compressor, a filter of a large size for the expected flow rate and with design characteristics appropriate to the ambient environment and the particle size of potentially present dust or impurities. During compression, the air heat up considerably. In the case where, depending on the use, the air has to be cooled, it is installed at the delivery of the compressor a tube beam cooler, with a large exchange surface and minimum loss of load, suitable to reduce the compressed air temperature to even just a few degrees above the available water temperature.