Excellent performance with Piston Air Compressors

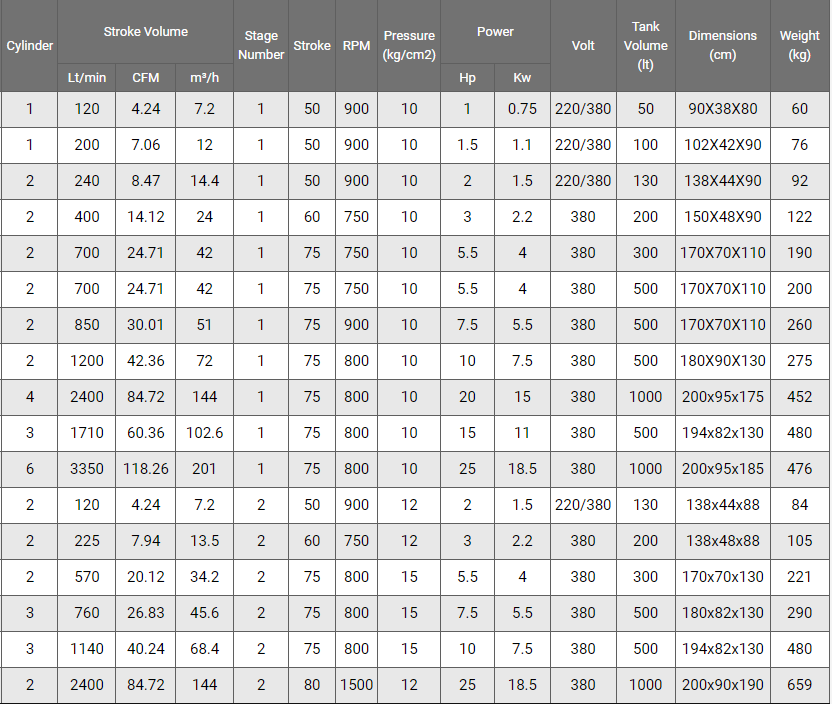

Compressor has been designing & manufacturing single stage, double stage and high pressure air compressors since 1978 according to work safety principles. Plenty of spare parts, extensive service network and 2 year factory warranty can meet your expecteations in Piston air compressors. Our free air delivery capacity starts with 120 liters per minute up to 14.400 liters per minute range.

General Advantages of Piston Air Compressors

Fully Automatic

Fully Automatic

Proper design for long-term productive use

Proper design for long-term productive use

Simple & balanced.

Simple & balanced.

In constructions, effective cooling by wide cooler flaps on top of pulley provides plenty of airflow and large surface wings of cylinders generates efficient cooling.

In constructions, effective cooling by wide cooler flaps on top of pulley provides plenty of airflow and large surface wings of cylinders generates efficient cooling.

Decreases mechanical frictions by ball & needle bearings

Decreases mechanical frictions by ball & needle bearings

Simple & effective lubrication & balancing of rotational parts.

Simple & effective lubrication & balancing of rotational parts.

Valve system which minimize the dead volume.

Valve system which minimize the dead volume.

Local manufacturing, plenty of spare parts.

Local manufacturing, plenty of spare parts.

Operation of piston compressors

Piston compressors, compress & store the free air. Head group is driven by electrical motor via V-belt and crank movement provides reciprocating movement of pistons. Pistons generate vacuum while going downwards from top point. The generated vacuum opens the suction valve and provides the filling of air inside the cylinder. When the piston starts to rise again, the suction valve closes and it also opens the valve at the outflow line thus the compression process starts accordingly.The compressed air passes over the pipe lines and reaches in non-return valve. Non-return valve keeps the pumped air inside air receiver and it ensures the full storage of compressed air in air receiver. Meanwhile, when piston compressed the air, air expands and heats up accordingly. The components which are being heated by the fan blades in the head group, blow the air they sucked to provide cooling.