Energy saving Soft Drive Models of Yiğitsan Screw Air Compressors

Running a standard air compressor constantly in maximum capacity seems theoratically right. However, according to some technical researches, during compressor’s working period in maximum capacity, between %50-%70 of its capacity can be used. This situation leads to higher energy consumption. Yiğitsan Compressor also manufactures inverter applicated Soft Drive Type Screw Air Compressors which reduces energy consumption. Soft Drive models adjusts the motor speed of the compressor according the pressure needs of the factory momentarily, thus increases the efficient life of compressor’s electric motor & rotary screws.

The inverter runs your compressor in variable r.p.m. (frequency) ranges so it adjusts the actual air needs of your installations automatically, hence increases the essential life-time of the valuable parts of the compressors such as mechanical, constructional & electrical equipment of compressors.

The inverter runs your compressor in variable r.p.m. (frequency) ranges so it adjusts the actual air needs of your installations automatically, hence increases the essential life-time of the valuable parts of the compressors such as mechanical, constructional & electrical equipment of compressors.

Soft Drive Compressors with their inverters, provide totally %25 – 35 energy saving, because of this energy saving, they pay back their costs to your company back.

Soft Drive Compressors with their inverters, provide totally %25 – 35 energy saving, because of this energy saving, they pay back their costs to your company back.

Also compressors with inverter, extends the valuable life time of equipments which use compressed air constantly.

Also compressors with inverter, extends the valuable life time of equipments which use compressed air constantly.

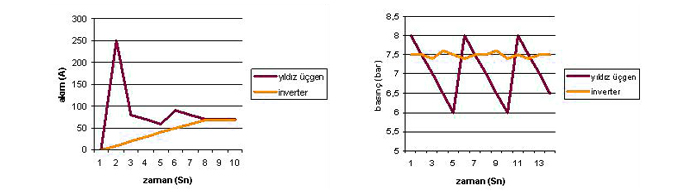

Smooth Start & Stop

Electrical motor’s Star-Triangle starting stage, they usually consume excessive electrical current, so they cause electro-mechanical losses and possible risks. However in inverter applications by smooth starting & stopping priviledge, the compressor’s and its equipment’s productive life cycle will be extended.

Constant Pressure

In standard compressors, target air pressure has been decharged without usage and when the pressure decreases to the bottom level, it starts to load air again to the target pressure. At this conditions, the air pressure decreases and increases constantly.

However with inverter applicated compressors, they adjust the motor’s r.p.m. and the compressors can stay at the target pressure constantly.

Operational Advantages

In off-load running periods, Standard Compressors without inverters consume %30-40 energy comparing their on-load periods. Briefly, during off-load running cycles, they consume excess energy without any work. This means continious electrical consumption, continious operation of bearings, continious circulation of oil, continious friction of running V-Belts.

In Soft Drive compressors with inverters, during off-load periods, they reduce power consumption they provide all the operational values in balanced level.

These compressors produces air as just in time principle and they consume the energy less than standard compressors. Briefly energy, in another way money consumption is limited accordingly.

Let your money stay in your pocket with Soft Drive Series Screw Air Compressors.