YVK Series

Compressor has been manufacturing Rotary Screw Air Compressors for Industrial use in collaboration with the world’s leading organizations in its field and it has been achieving productive & satisfactory results in maximum levels.

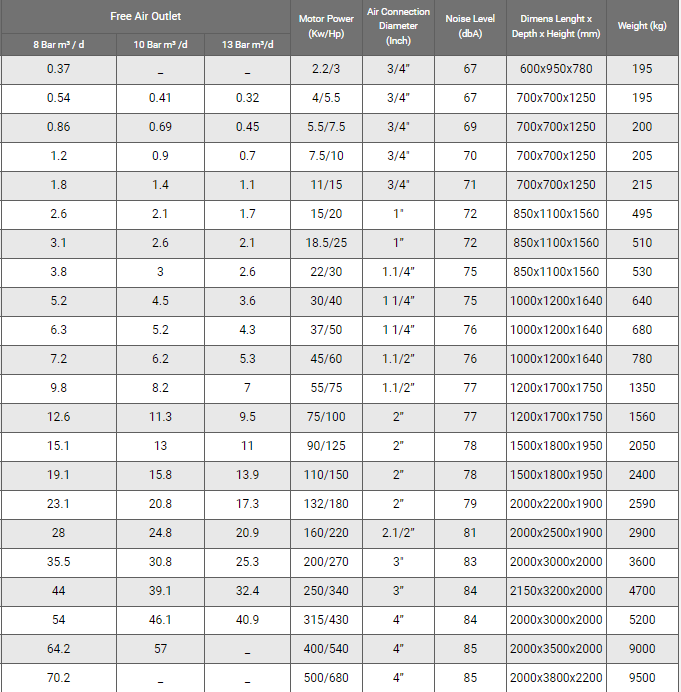

In Stationary Screw Air Compressors we have been manufacturing items starting from 0.43 m3 / min. up to 70 m3 / min. free air delivery capacities in our own factory and for more larger capacities we can work according to exclusive orders.

Yiğitsan supplies screw air compressors with their required free air delivery capacities & pressure values, designed as workplace safe, energy-efficient, productive items in efficient capacities and have plenty of spare parts.

The air is being sucked in the Air filter inlet before compression, this Air is being compressed inside the High Technology Air-End. This Air-End can be driven by Electric motor or Diesel/Petrol Engines. For cooling down the rising temperature in the Air-Dryer and lubrication purpose, the oil is being injected into the Air-Dryer. Oil separator will separate the oil from the pressurized air’s vapour. The separated oil and the oil which is in circulation by internal pressure without any oil pump need, is being cooled down in the cooling chamber than passes through inside the oil filter, than returns to injection area. The Oil injection circulation continues in this way.

Compressed air, is being separated from the oil by air/oil separator, than passes through minimum pressure valve and reaches to the Cooler. Cooling Air is being sucked by dust absorbant filter and initially cools down the equipment in the compressor and passes through the Aluminium block type Cooler and releases the air outside.

Thereby, the equipment inside the compressor are being cooled down and

- Constant Control Feature by the calibrated measurement Devices/Tools.

- Constantly improving Research & Development Activities.

- Practical & Affordable maintenance advantage.

- Anti-corrosive, Scratch resistant, Environmental friendly Powder Paint.

- Punctual intervention by Expert, well-trained and positive After-Sales Team.

- Avoiding Troubles by Long time Testing and Experimentation procedures.